! REPORT

Corellian Courier WIP 02

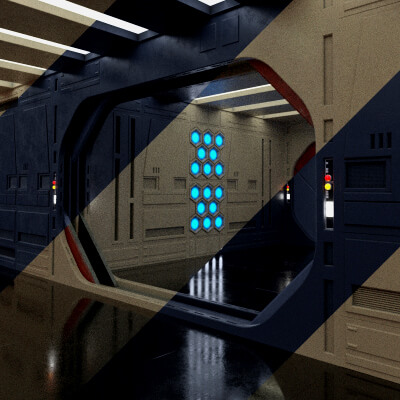

3D Render by TALON-3DJust like the movie franchise that has inspired this design, the development of this model has become something of a saga, stretching over years and morphing in unexpected directions, but it has never been anything less than fun to work on, and something of an education. The exterior mesh is pretty much completed, with the detailing continuing forward along the hull, and so it no longer just magically floats there, landing gears at long last have been added (front gears partially inspired by an early Ralph McQuarrie concept for Han Solo's Pirate Ship). This has resulted in a model I am most happy with. But while I still need to build a full interior for this and texture it to get full value out of it in a 3D CGI environment, such as a game engine, or something like Daz 3D, I've gone off on an interesting, but unexpected tangent with it.

While this has been in production a lot have people have asked whether I'm going to make this available for 3D printing, or make a kit of it. And this intrigued me, and I have often wondered about how easy or difficult it is to develop assets for 3D printing. The needs will obviously be different to that of an asset developed purely for in engine or a CGI environment, that just has to look cool and functional, whereas with 3D printing it needs to actually work as a real world 3D object and have a watertight mesh and higher mesh density, there are no Smoothing Groups in the real world after all. But how hard could it be? So I've decided to "Go Big or Go Home" as it were, and go down a development tangent for this model and create a version of it for 3D printing.

I've been lucky in that I've been able to get in contact with people already very experienced in this field, and they have been very generous and forthcoming with their time and advice, and as such I already have had some parts test printed, and even these early results are very exciting.

So watch this space, there are some fun times ahead.

(Many thanks to both Tom Wykes and Andrew Pattenden for their valuable advice and assistance with the 3D Printing aspects of this project)

While this has been in production a lot have people have asked whether I'm going to make this available for 3D printing, or make a kit of it. And this intrigued me, and I have often wondered about how easy or difficult it is to develop assets for 3D printing. The needs will obviously be different to that of an asset developed purely for in engine or a CGI environment, that just has to look cool and functional, whereas with 3D printing it needs to actually work as a real world 3D object and have a watertight mesh and higher mesh density, there are no Smoothing Groups in the real world after all. But how hard could it be? So I've decided to "Go Big or Go Home" as it were, and go down a development tangent for this model and create a version of it for 3D printing.

I've been lucky in that I've been able to get in contact with people already very experienced in this field, and they have been very generous and forthcoming with their time and advice, and as such I already have had some parts test printed, and even these early results are very exciting.

So watch this space, there are some fun times ahead.

(Many thanks to both Tom Wykes and Andrew Pattenden for their valuable advice and assistance with the 3D Printing aspects of this project)